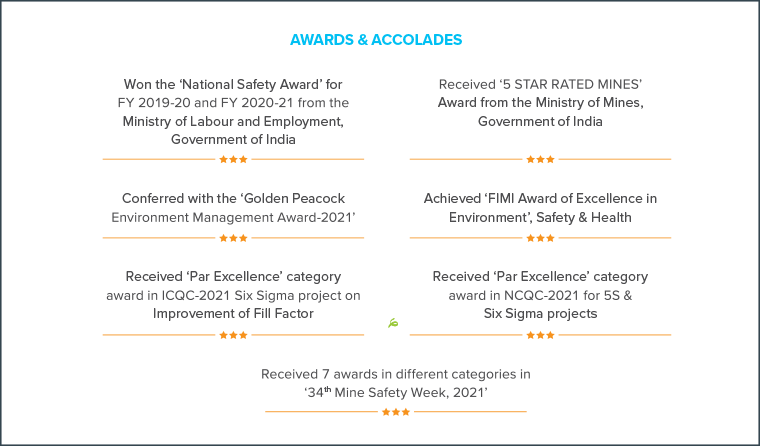

At Hindustan Zinc, we remain committed to sustainable mining backed by focussed investments to enhance safety, productivity, and efficiency at our mines. We are leveraging automation and technology to make our mines safer, in line with our Sustainability Goals 2025. Our efforts are also centred on making our mines more environment-friendly to steer our decarbonisation journey

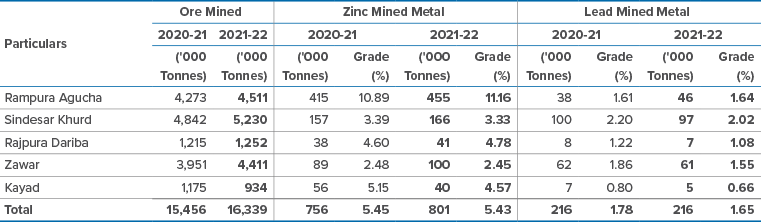

FY 2021-22 marked a major milestone in terms of our bestever mined metal production of 1,017 kt, up 4.6% year-on-year. We celebrated the crossing of the one million tonnes production mark on account of higher ore production across most of our mining locations.

The operational excellence we delivered during the year was the successful manifestation of our diligent and innovative approach. Confronted by various setbacks and hurdles, we gained from our learning experiences to emerge stronger and better through the highs and lows of the year. This translated into improved performance and new highs in MIC delivery, ore hoisting, Zn & Pb recoveries, and other areas. We are well and truly on course to usher in a new era of growth and set global benchmarks through our breakthrough innovations, centre of excellence and digitalisation drive. Our renewed focus on steering safety (zero harm), innovation, quality, automation and optimal operational metrics will help us raise the bar of excellence. It will enable us to push the momentum of growth further as we surge towards enhanced capacities and capabilities.”

Praveen SharmaCOE Mining - Head

Being the flagship mine of Hindustan Zinc, Rampura Agucha Mine is at the forefront of operational excellence. The mine is one of the most mechanised and digitally-driven underground mining locations. We are continuously endeavouring to scale the mine’s operations and remain focussed on sweating the assets effectively.

We are focussed on upgrading the maintenance infrastructure and practices at the mine, concertedly implementing best-in-class operating practices and focussing on improving the skill level of our workforce with the aim of developing the RA location as a Model AO location.”

Kishore Kumar SChief Executive Officer - Agucha IBU

Having set in motion a well-articulated plan to create a unique digital-enabled mine, we are now focussed on proactively leveraging digital capabilities, including Artificial Intelligence (AI), through targeted initiatives. The focus, going forward, will be not just on improving the operational efficiencies at the mine through acceleration in its digital and technology transformation but also on creating a 100% safe working environment for our workforce and business partners. Building capabilities to detect deviation from our safety standards, using wi-fi to track movement of personnel and equipment in the underground mine, enabling tech-enabled remote operations and powering smoke hour drilling have emerged as some of the key areas of focussed intervention. While improving the safety environment and reducing the operational cost of extraction, these initiatives will also help lower our carbon footprint in line with our strong ESG commitment.”

Vinod JangirChief Executive Officer - Dariba IBU

The historic high 1 Mtpa production milestone notched by Hindustan Zinc during FY 2021-22 underscored the success of our efforts towards building a culture of robust mine planning, aligned to global standards. We have designed our planning processes to the organisation’s long, medium and short-term goals and vision. Our efforts are now steered towards progressing further on the roadmap for achieving 1.2 Mtpa mine capacity in the near term, at the back of our sustained focus on more seamless mine planning and safety augmentation. We are optimistic about achieving our targets with the help of the best-in-class professionals hired from across the global at our locations and the nurturance of a sustainable culture across the organisation. For long-term mine planning and design, we have prioritised in-house capacity building as a key thrust area, which we shall make strategic investments in strengthening in the months ahead.”

Vinod KumarChief Executive Officer - Zawar IBU

The Rampura Agucha Mine (RAM) is an ISO 9001, ISO 14001, ISO 45001, ISO 50001 and SA-8000 certified underground zinc and lead mine. Located in the Bhilwara district of Rajasthan state, RAM is the largest and richest, lead-zinc deposit in the country and among the world’s largest with 75.0 Mt of ore reserves and resources (R&R) with in situ average grade of 10.8% zinc and 2.0% lead on an exclusive basis as on end of FY 2021-22. It is also one of the lowest cost zinc producing mine globally. The mine is equipped with best-in-class infrastructure, operates at high levels of ESG standards, deploys advanced technology for mining activities for better targeting and has some of the best people in the mine’s leadership, with extensive community outreach.

The Rampura Agucha Mine continued to scale its operations with focussed interventions on operational and technology fronts and new targeted initiatives that led to a 5.6% year-on-year increase in ore production and 10.4% increase in mined metal production over the previous fiscal. RAM is currently producing at 4.5 Mtpa through its underground operations. It is in the process of building infrastructure to support its expansion plan to enhance ore production beyond 4.5 Mtpa.

During FY 2021-22, RAM crossed several notable milestones to propel its journey of operational excellence and growth.

To create a more enabling environment for future growth, RAM initiated a host of expansion, upgradation and infrastructure development initiatives during the year which are at various stages of completion.

Rampura Agucha has successfully commissioned its 2nd underground crusher along with conveyor system enabling full utilisation of 3.75 Mt main shaft hoisting capacity

To boost its operational efficiency and productivity, RAM initiated several concerted measures during the year, particularly in the areas of technical advancement, digitalisation, and automation.

This highly digitalised and connected command centre offers end-to-end monitoring and controlling of all mine facilities through a single operator interface for complete operation of mine services

This will enhance safety, improve productivity of resources, manage traffic and create an advanced technical environment for the workforce

It includes use of Optimine, Certiq and OSI PI data visualisation tools, thus increasing utilisation of resources

This helps to reduce machine to machine and man to machine interaction

This will automate the dewatering operations, further creating dashboards to bring real-time updates of drilling water and dewatering status to surface

RAM’s efficiency and productivity boosting efforts during the year included several new training initiatives. The mine launched the first-of-its-kind virtual reality-based winder simulator in the industry, for ground-mounted Koepe winder system. It also organised a mining mate skill upgradation training programme by a retired DGMS official.

As RAM is getting deeper, the mine will be associated with seismic activities. To monitor the seismicity, real-time seismic monitoring system has been established in the mine. The system provides real-time information about the exact hypocentre, intensity and frequency of event, which helps in making strategic decisions like stoping sequence and ground support design.

As part of the initiative

Real-time micro-system monitoring system has been installed with 10 sensors covering entire UG working.

Benefits

Based on the monitoring data, stoping sequence can be optimised for minimising seismicity.

Proactive modification of ground support.

As the monitoring system gives exact hypocentre and magnitude of event, the area can be isolated to minimise exposure of men and machine.

The stage pumping network, with frequent pump breakdowns, was causing sump overflow as well as waterlogging at RAM. Further, inefficient slurry handling was leading to gradual mud settlement in the sump. Concerned about this situation, the RAM team sought solutions to enhance the mine dewatering capacity and eliminate stage pumping.

As part of the initiative:

Benefits

As a result of installation of this fully automated pumping system:

Sindesar Khurd (SK) Mine is a world-class silver-rich mine with state-of-the-art infrastructure facilities and best-in-class mechanisation. Since it commenced operations in 2006, the mine has undergone several phases of expansions – from 0.3 Mt to its current capacity of 6.0 Mt. SK Mine today stands out as one of the largest underground mine and one of the lowest cost silver producer in India. The deposit at SK Mine has a main lens and multiple standalone auxiliary lenses, creating multiple independent production centres.

In FY 2021-22, SK Mine witnessed 8.0% increase in ore production over FY 2020-21. The Mined Metal Production for the period grew 2.4% year-on-year. Powered by focussed exploration, ~22 kilometres of mine development took place during the year, enabling SK Mine to scale up production and boost its future-readiness.

SK Mine witnessed steady progress on various projects undertaken during the last fiscal year.

The focus on expansion, upgradation, and development of new infrastructure at SK Mine was further sharpened during the year.

Various targeted initiatives were implemented during FY 2021-22 to enhance the mine’s efficiency and productivity metrics.

Successfully implemented pilot project for Tele-remote drilling with the deployment of technologically advanced drills

Improvement in recovery of zinc in the beneficiation plants

Installation of chiller units (60 m3/s) at surface for intake air, to provide cooled air at working face in mine’s deepest areas; helped improve the ambient working conditions in summers, resulting in enhanced productivity and efficiency

Real-time monitoring of underground vehicles and persons

Underground pumping automation implemented at 3 pumping stations; another 12 pumping stations’ automation to be taken up in FY 2022-23

Integration of shaft system with OSI-PI system for improvement in shaft productivity and reliability

Implemented Skip Rope anomaly detection system for early detection of wire rope defects with position and reduction in manual inspection time

Short Interval Control (SIC) established in operational planning to leverage technology in day-to-day activities of planning, scheduling and tracking

SK Mine took a major leap forward in furtherance of Hindustan Zinc’s sustainability goals during the year.

Mill-specific power consumption reduced from 31.9 kWh/MT in FY 2020-21 to 31.0 kWh/ MT in FY 2021-22 as a result of Variable Frequency Drive (VFD) installation in water pumps

Recovery of water from tailing dam increased by 10% over FY 2020-21

Challenged by delays in power restoration in case of tripping, SK Mine undertook automation of substations across 12 of its electrical substations. The digitalisation initiative involved connecting the HT and LT incomer MFR and On/Off signal to the network, so that the connected substation could be accessible from the surface as well as underground.

What prompted the initiative was the challenge faced by the mine in case of power tripping. SK Mine took a root cause analysis approach to minimise the time taken in troubleshooting. With the aim to improve and optimise energy consumption, the team decided to automate all substations for faster troubleshooting and reduce non-working hours due to power tripping

As part of the initiative, the following measures were adopted:

Benefits

As a result of the digitalisation exercise:

Seeing drilling machines lying idle during smoke hours, SK Mine took the initiative for full-scale implementation of automation in all capable drill rigs, to utilise smoke hours for productive drilling. With the aim of getting extra drilling, SK Mine decided to use the new-generation drill rigs, equipped with the capability of single hole automation (down-hole) and fan automation (up-hole).

The idea behind the project was to productively utilise smoke hours, or the time duration provided for clearance of blasting fumes from the mine before re-entry of persons in shift changeover.

As part of the initiative, the following measures were adopted:

Benefits

As a result of the digitalisation exercise:

The underground Rajpura Dariba (RD) Mine is one of our oldest mines, which commenced operations in 1983. The lead-zinc mine is accessed via decline, main shaft, and auxiliary shaft. We are in the process of augmenting the production capacity to 2.0 Mtpa >> 4.0 Mtpa. The capacity enhancement will be achieved through the introduction of two new portals for upper east and north lode, through further mechanisation and automation.

FY 2021-22 was a stepping-stone for Rajpura Dariba mine’s capacity expansion on multiple fronts. Ore production witnessed an increase of 3.1% y-o-y, while mined metal production increased by 2.6% y-o-y.

Despite the pandemic situation, RD Mine undertook several major projects during the year, commissioning of separate compressor and drilling water line for north lode, besides sump commissioning for M5 block.

FY 2021-22 saw RD Mine post many new milestones in terms of expansion, upgradation, and infrastructure development.

A slew of projects enabled RDM to improve efficiency and productivity during the year.

1,100 metres ramp stripping done to incorporate 45T LPDT, leaky feeder infrastructure, and to reduce equipment damage incidents

Expat operator and trainers brought in to operate fully automatic Simba drill machine to improve drilling capacity

Single backfill line installed from surface to 11 mRL, replacing staggered old line

Infrastructural strengthening of mill done to improve operational efficiency and throughput

Replaced main-shaft old cage with new fully enclosed designed cage to improve person safety and skip run hour

Installed and commissioned continuous ambient air quality monitoring system to help establish and improve over baseline ambient air quality

Introduction of dry tailings and paste-fill plant for optimum utilisation of tailing, reducing tailing discharge to tailing dam (step towards ZLD), and to improve mining condition by reducing overall water intake for underground mining

To strengthen the overall shaft structural stability and safety, and augment the hoisting capacity of the mine, RD Mine initiated infrastructural upgradation and development during the year. A key feature of the project was its Zero Harm execution. The project was supervised by a specialised female expat officer to ensure safe implementation.

The move was triggered by RD mine’s decision to enhance its ore production capacity to 1.3 Mtpa in FY 2021-22. RD Mine further plans to ramp-up capacity to 2.0 Mtpa in the next fiscal by increasing the ore hoisting capacity of the shaft from the current 0.9 Mtpa to 1.35 Mtpa, through augmentation of skip speed, payload and running hours.

As part of the Initiative:

Benefits

As a result of the structural upgradation exercise:

Surging ahead on its growth journey, Zawar Mines (ZM) crossed the major milestone of 4 Mt ore production mark in FY 2021-22. This group of four heritage mines, with mining history spanning over 2,000 years, celebrated many iconic achievements during the year. The four underground mines – Mochia, Balaria, Zawarmala and Baroi, also scaled new levels of mechanisation and digitisation. The mines, located 40 kilometres southeast of Udaipur in the state of Rajasthan, successfully harnessed various technological advancements to report exemplary performance during the year.

The Zawar Mines touched new frontiers of growth and expansion during FY 2021-22, discovering new lenses and achieving overall milling recovery of 90.80%.

Zawar Mines continued its efforts to strengthen mine infrastructure during the year.

Mochia Mine, Baroi Mine and Balaria Mine crossed the highest ever figures for production, development, drilling and MIC during the year.

To further boost efficiency and productivity of the mines, a series of initiatives were undertaken during FY 2021-22.

Establishment of centralised control room at Balaria

Digital enablement of visibility of equipment utilisation for identifying and minimising idling in Mochia and Baroi

Installation of Mine Communication System using Leaky Feeder in Mochia, Balaria & Zawarmala

Zawar Mines initiated many significant projects programmes to propel its sustainability agenda.

Introduced first surface and underground electric vehicle

Initiated establishment of 4 MLD Zero Liquid Discharge (ZLD) Plant

The losses resulting from sub-optimal utilisation of transportation systems was a cause for concern at Zawar Mines. It was significantly affecting the mine’s operating costs and leading to delays in delivery of necessary materials. Poor optimisation of material hauling, and triaging was further resulting in under-utilisation of the trucks and vehicles at the mining site.

Zawar Mines decided to undertake digitisation to enhance the visibility of equipment utilisation,with the aim to minimise the idle time of LPDTs underground.

As part of the initiative, the following measures were adopted:

The benefits

Located in Kayad, Ajmer (Rajasthan), this underground mine has been delivering a consistent 1.2 Mt of ore with approximately 60 kt of metal in concentrate over the past five years. Our youngest mine, which started operations in 2011, has produced more than 6 lac tonnes of metal content in the past eight years at the back of high level of mechanisation and digitalisation. Ore produced from mine is transported to RA Mine mill, Bhilwara, for beneficiation. Operations are vertically integrated and supported by continuous and integrated surface and underground exploration

In FY 2021-22, Kayad Mine (KM) produced 934 kt of ore, with 44.3 kt of metal in concentrate. With 7.4 kilometres of development in existing and upcoming blocks, it is poised to maintain its current production rate in the coming years.

While investing in new infrastructure and development, Kayad Mine also commenced operations on the projects initiated in FY 2021-22 and reported

During the year, KM successfully established infrastructure and ventilation in auxiliary lens for next year’s production. This included:

A slew of innovative measures were undertaken at Kayad Mine to boost efficiency and productivity.

Kayad has successfully shifted to the Mine Development Operator modality, keeping a single stakeholder responsible for core operations the Mine Development Operator modality, keeping a single stakeholder responsible for core operations

Mine planning teams continually monitor ore yields and methods to further enhance the same through digitalisation and use of advanced technologies to improve operational efficiency. Operations are focussed on ensuring high recovery of ore and minimise the loss of metal, while maintaining operating costs at the lowest possible levels

Kayad Mine has installed a Level Transmitter to determine the level to which the silos are filled with cement, that helps to estimate the quantity of cement in each silo. DPT is further being used to measure the flow of cement.

Kayad Mine implemented a series of new initiatives during the year to augment its safety proposition.

Consumption optimisation

Minimisation of bucket repairing and fabrication cost

To identify areas for improvement, a robust skill assessment exercise of Kayad mine’s executive employees was undertaken during the year under review. Based on the assessment, a training calendar was prepared to ensure skill gap mitigation for all manpower at the site. Further, to boost productivity, and to assess the safety and operational improvement areas, a skill mapping and assessment exercise was also carried out for contract workers.

A special training programme on Cracking FCMM Certifications was held with the support of an expert former government official. Barring two, all participants passed the exam, aimed at building a robust talent pipeline.

This was conducted by ex DDG, DGMS, to improve the competency levels of mining mates with respect to their roles, responsibility, hazard identification and risk assessment.

In line with its concerted focus on sustainable development, Kayad Mine took various measures during the year to ensure the following:

Kayad Mine is monitoring real-time power generation and consumption metrics, along with other critical working parameters of all inverters. Solar site monitoring is done using a specialised camera to assess the physical conditions at the site, besides ensuring upkeep to avoid any interruption to the operations.