A sustainable business is one that serves an enduring purpose in society, and considers, in all its decision-making, the varied forms of value it can deliver to all stakeholders, including the natural environment. We, at Hindustan Zinc, have made sustainability central to our growth and value-creation journey, and remain focussed on ensuring safe operations with minimum environmental impact of our business across the lifecycle. We have ingrained into the organisational fabric a strong sense of respect for human rights, and the ethos of sharing the benefits of business with our stakeholders. Our strategic approach is aligned with national and international standards, Sustainable Development Goals, and driven by the vision of the Company’s leadership.

In the year 2020, we set out a series of goals, spanning the full breadth of Environmental (E), Social (S) and Governance (G), in the shape of our Sustainability Goals 2025. While we have made good progress towards the delivery of those goals, we recognise that as the world changes, society’s expectations from us also evolve. Our commitments must be relevant and capable of bridging any gaps, to help the business expand. Just as financial performance presents an opportunity for differentiation, we see sustainability no differently – it is integral to our work, and business performance.

BEING AMBITIOUS, BEING AUDACIOUS

Our sustainability vision is centred on ‘ZERO HARM, ZERO DISCHARGE, ZERO WASTE’, and our ambitious sustainability journey is steered by our Sustainability Goals 2025. For us, these goals constitute an action agenda to achieve our long-term ambition of creation and delivery of value to our stakeholders, across the value chain. We strongly believe that these goals will enable us to address the expectations of our stakeholders, while giving us many reasons to celebrate our journey of inclusive and holistic growth, and value creation.

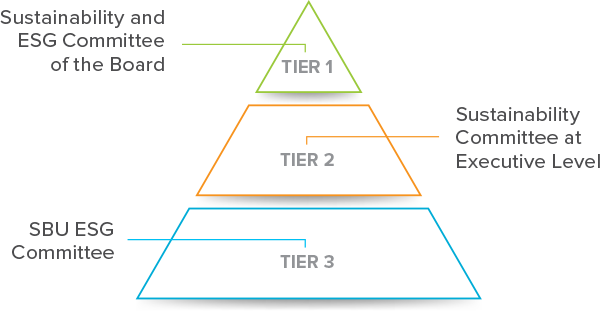

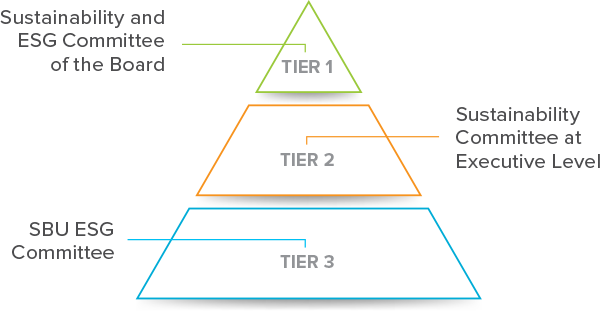

OUR SUSTAINABILITY GOVERNANCE FRAMEWORK

At Hindustan Zinc, we have implemented a three-tiered sustainability governance framework to organise our thoughts and ideas, undertake informed planning, evaluate activities, and ensure accountability on all aspects of environmental, social, and governance issues. The framework also enables us to set short-term and long-term goals and monitor performance systematically in alignment with our sustainability priorities at every level of the organisation.

TIER 1

SUSTAINABILITY AND ESG COMMITTEE OF THE BOARD

During the year, we enhanced our focus on sustainability and ESG by constituting a separate Sustainability and ESG Committee at the Board level. The committee consists of four members, and its meeting for FY 2021-22 was held on December 27, 2021. The role of the Sustainability and ESG Committee is to assist the Board in meeting its responsibilities in ESG matters and to ensure strong governance for sustainability. It is responsible for providing guidance to ensure continual improvement in our sustainability performance and the implementation of appropriate processes and policies across the Company. The committee is responsible for structuring our sustainability strategy, and long-term goals and targets. It also plays a key strategic role in business decisions to ensure workplace safety, eliminate potential damage to the environment, enhance our commitment towards stakeholders, and maintain the Company’s reputation as a leader in the sustainable metal and mining sector.

TIER 2

SUSTAINABILITY COMMITTEE AT EXECUTIVE LEVEL

We have established an Executive Sustainability Committee, chaired by the Company’s CEO and involving all the 10-communities heads and executive committee members. The committee meets monthly to review the progress on all Sustainability Goals 2025. It is responsible for formulating the sustainability strategy, and the long-term goals and targets of the Company. It plays a strategic role in all business decisions for ensuring workplace safety. The focus is on eliminating any potential damage to the environment, in line with the Company’s stakeholder commitment and maintaining its reputation.

To drive the Sustainability Goals 2025, we have established the following sustainability communities to review progress against their respective goals. These committees that comprise the champions of all the units, meet once a month.

TIER 3

SBU ESG COMMITTEE

We continually identify, assess, and mitigate risks arising out of internal and external factors. To ensure an internal formal monitoring process at the Company level, new risks are identified, categorised as per impact and likelihood, and mapped to key responsibilities of certain managers. More than 100-line managers are aligned within a structural governance set-up across all SBUs to manage risks with an appropriate mitigation plan and to drive the ESG agenda.

COMMITTEE COMPOSITION

Mr. Akhilesh JoshiNon-Executive - Independent

Director - Chairperson

Mr. Arun MisraExecutive Director - Member

Ms. Nirupama KotruNon-Executive - Nominee

Director - Member

Ms. Veena Kumari DermalNon-Executive - Nominee

Director - Member

Various sub-goals and action plans have been identified for the implementation of planned goals and their effective monitoring. These action-plans have been discussed in detail in our Sustainability Review Report.

OUR SUSTAINABILITY GOALS 2025

1. CLIMATE CHANGE

0.5 Mn TCO2e GHG emission savings in our operations from base year 2017

- Focus on renewable energy

- Electrification of vehicles

- Efficiency improvements

2. WATER STEWARDSHIP

Become 5x water positive company and achieve

25% reduction in freshwater

- Exploring alternative water sources

- Reduction in fresh water through technological interventions

- Rainwater harvesting

3. CIRCULAR ECONOMY

3x Increase in gainful utilisation of smelting process waste

- Eliminate generation of landfill waste

- Gainful utilisation of waste in other industries

- Metal recovery from residue

4. SOCIAL IMPACT

Positively impacting 1 million lives through social, economic, and environmental initiatives

- Strengthening the local economy

- Promoting skilling and education in the region

- Improving quality of life of communities around us

5. BIODIVERSITY CONSERVATION

Protect and enhance biodiversity throughout the life cycle

- Reassessment of biodiversity and development of biodiversity management plan

- Implementation of critical/ endangered species conservation plan

- One million plantation drives

6. DIVERSITY IN WORKFORCE

Inclusive and diverse workplace with 30% diversity

- Improve diversity in the organisation (Gender, LGBTQ, Special Ability)

- Review of current policies and framing of new conducive policies

- Developing/grooming high potential diversity employees through various programmes

7. ENSURING ZERO HARM

Zero Work-related fatalities and 50% reduction in Total Recordable Injury Frequency Rate (TRIFR)

- Safety culture transformation

- Visible felt leadership

- Critical risk management

- Process safety management

- Business partner skill enhancement

- Technology and innovation

8. RESPONSIBLE SOURCING

100% Responsible Sourcing in the supply chain

- Implementation of LME responsible sourcing guidelines and OECD framework

- Supplier sustainability assessment

- Human rights training and awareness

- Ensuring local procurement

In addition to specific initiatives,

we also continued, during the year,

to drive our ongoing technological

and operational initiatives

towards the realisation of our

circular economy goals.

CIRCULAR ECONOMY – A KEY STRATEGIC PRIORITY

The circular economy entails elimination of waste throughout our entire value chain and works to establish a net-positive system to ultimately protect the Earth’s finite supply of natural resources. As a leading organisation, we promote responsible production of materials. We comply with all regulatory requirements and have the necessary permits for treating and recycling waste at our operation site.

Our waste to wealth community is continually working on optimising use of raw materials and exploring ways to reuse/ recycle the waste products created during the manufacturing process. It regularly monitors and reviews the progress on this front and formulates relevant strategies to achieve ‘Increase in 3x gainful utilisation of smelting process waste’ – one of the Company’s Sustainability Goals 2025.

During the year, we took several innovative initiatives to steer the shift from traditional manufacturing approach of ‘produce-use-dispose’ to a more efficient, sustainable, and environment-friendly methodology.

These include:

RO REJECT SALTS

The Sodium Sulphate Recovery Plant at Dariba Smelting Complex is operational and the quality of salt generated is suitable for jarosite precipitation, a procedure for removal of iron and lead impurities during zinc extraction. This has reduced hazardous mixed salt generation by ~10%.

We conducted a detailed analysis of RO rejects mixed salt generated at Debari and Dariba smelter. Mixed salts generated from Dariba Zinc smelter, were found suitable for use by the soap industry, targeting utilisation of 1,500 tonnes of mixed salt in the manufacture of soap and detergent instead of being disposed in a Secured Landfill Facility (SLF).

DISRUPTIVE TECHNOLOGIES

We are working in collaboration with various national and international institutes and technology providers for metal recovery and utilisation of tailing and jarosite. There are ongoing laboratory trials to evaluate the techno-economic feasibility of metal recovery from Rampura Agucha Mine tailing and jarosite/jarofix generated in our smelters.

JAROSITE UTILISATION

During the year, 93,778 tonnes of Jarosite has been gainfully utilised in cement manufacturing. To further enhance Jarosite utilisation in cement manufacturing, we have been able to control the moisture content in Jarosite by optimum use of reagents, with this successful trial. We are targeting nearly 2 lac tonnes of Jarosite utilisation in FY 2022-23.

WAY FORWARD FOR JAROFIX UTILISATION

The Company has been granted permission by Rajasthan State Pollution Control Board for gainful utilisation of jarofix waste in the construction of roads and highways, including embankments. We have partnered with some government agencies like NCCBM, NEERI and CRRI for the utilisation of jarosite in cement and road construction.

R&D, DIGITISATION AND CIRCULAR ECONOMY

Our Research and Development (R&D) capabilities are playing an important role in propelling our circular economy goals. We are exploring various technologies for metal recovery from various residues and waste. R&D has taken up the challenge to increase metal recoveries and improve the process efficiency by implementing geo-metallurgy at mills and tracking of losses in tailing through an automated minerology setup. On smelting R&D is developing sustainable technologies in-house and in collaboration with institutes and technology providers.

The Company has been able to improve its metal recovery from beneficiation plants through digitalisation.

ADVANCED CONTROL OPPORTUNITY FOR GRINDING AND FLOTATION CIRCUIT

To address the difficulty in flotation process plants coming from the constantly changing feed characteristics.

An Advanced Process Control (APC) System was introduced to stabilise circuit operations while optimising the process performance to maximise metal recovery. Three APCs were implemented for grinding and flotation operations (Lead and Zinc) in mills at Rampura Agucha and SK Mines.

Consequently,

- Pb Recovery Improved by 0.9% while moving concentrate grade distribution on higher side

- Zinc Recovery improved by 0.9% while narrowing concentrate grade distribution around target