At Hindustan Zinc, we have aligned our responsible sourcing ethos with our Vision to create an efficient supply chain, with focus on total cost of ownership, technology, innovation, and governance. We follow a collaborative partnership approach to drive efficiencies and sustainability, and to create value across our business eco-system. We are proactively focussed on nurturing our relationships with business partners to ensure collective and sustainable long-term value creation.

(As of March 31, 2022)

Through our responsible sourcing focus, we are addressing a host of material issues which have the potential to impact our business operations, to varying degrees.

High Priority

Medium Priority

We encourage all our Business Partners to commit to Responsible Sourcing practices, develop long-term action plans and maintain high levels of compliance and performance aligned with Hindustan Zinc’s vision. Hindustan Zinc aims to work with top partners basis preferred performance on various responsible sourcing guidelines and parameters. In line with this, to achieve our goal of achieving 100% Responsible Sourcing by 2025, we continue to frequently engage with them through regular discussions, knowledge sharing & cross learning. We hosted webinars to align our Business Partners with our Business Plan and Sustainability Goals. We also engage in due diligence of the Business Partners which includes site visits and on-site engagement with the vendors. Hindustan Zinc believes in awarding and recognising our Business Partners to motivate their workforce and bring innovative solutions. We also host strategic Business Partner engagement sessions with our Senior Leadership to learn from the best practices of our Business Partners and support them in gaps identified. To ensure alignment of Business Partners with our vision of Zero Fatality, we impart regular safety trainings to our Service Business Partners.

*Basis the actual payment made to the Company’s Business Partner during FY 2021-22

*Basis Purchase Orders released during FY 2021-22

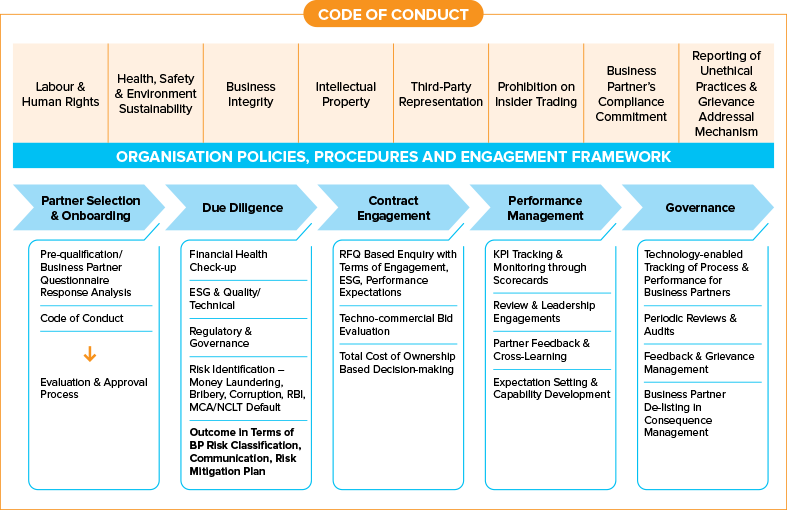

We have in place a robust business partner management framework, with a clearly defined code of conduct. The code is designed to ensure business partners’ compliance with the Company’s highest standards of integrity, transparency, and ethics.

Our Code of Conduct articulates the basic requirements we expect our business partners to respect and adhere to, when conducting business with Hindustan Zinc. It embodies our commitment to internationally recognised standards, including the core conventions of the International Labour Organisation, United Nations’ Universal Declaration of Human Rights, as well as prevalent industry standards, and all other relevant and applicable statutory requirements concerning Environment Protection, Minimum Wages, Child Labour, Anti-Bribery, Anti-Corruption, Health and Safety, with focus on requirements governed by the highest standards of conduct.

At Hindustan Zinc, we operate an exhaustive Business Partner monitoring and rationalisation system to ensure robust supply chain risk management. We ensure this through a combination of risk assessment and performance monitoring.

Business Partners are onboarded following detailed evaluation of qualification criteria. Those with issues in performance, in terms of quality and delivery, service KPIs or any other identified risk, are critically reviewed and monitored for performance improvement. In case of no improvement, their registration gets inactivated, and they are excluded from any further sourcing participation.

Business Partners are also subjected to strict desktop-based due diligence along with at-site audits based on various parameters.

An adverse case of a business partner’s ethical non-compliance, major quality failure, fraudulent behaviour, false representation, contractual default, breach of safety norms, violation of contractual terms or code of conduct etc., may lead to cancellation of their registration. These business partners are subject to stringent quality management, capability assessments through site visits, as well as audits and performance reviews.

Partnering OEMs on technological interventions

As part of this Initiative:

The Benefits

Operational excellence

We have developed a well-defined process for forging and strengthening robust and long-term partnerships to achieve sustainable and responsible sourcing.

Multiple methods, including market research & project-specific consulting engagement, Global Expression of Interest (EOI) on digital & print media, electronic marketplaces, online searches, direct approach, are used to identify potential business partners.

Transparent registration is done, through an online registration process on our SAP Ariba System. It involves filling up a detailed registration questionnaire form capturing key information, followed by evaluation and approval by designated authority. The questionnaire enables data collection on parameters like partner financial capabilities, quality, historical business performance, ESG, customer references and experiences.

Smoother experience is facilitated on the Ariba platform through an Ariba Helpdesk Team, which provides 24x7 support to business partners while onboarding and usage of Ariba. Business Partners are classified as Critical Tier-I and Critical Tier-II, based on assessment of supply chain risk, Hindustan Zinc’s business dependency, and contract spend across supply and service categories.

Identification of business partner risk in the value chain is vital to ensuring smooth supply chain operations.

Periodic due diligence, site visits and audits are conducted to identify risks.

As part of the due diligence, partners are subjected to financial health check-up, technical capability assessment, regulatory & governance checks, ESG/Quality compliance at site, risk identification in terms of money laundering, legal and regulatory compliances, fraudulent behaviour, corruption and others.

Due diligence is done through desktop-based data collection and analysis, declarations and on-site audits.

Based on the identified risks, suppliers are classified into different tiers, identified risks are communicated to partners and risk mitigation plans are prepared.

We have a pool of registered business partners who are eligible to conduct business with Hindustan Zinc.

Sourcing requirements are communicated to our registered partner base through an RFQ-based enquiry, along with clear terms of the engagement and detailed scope of work.

Bids received from business partners are subjected to techno-commercial evaluation.

Contract is finally awarded through reverse auctions based on total cost of ownership (TCO), subject to clearing techno-commercial bid evaluation.

Monitoring and evaluation of business partners’ progress is done in line with contractual KPI delivery, through performance tracker in the form of scorecards.

Periodic performance reviews and leadership engagements are undertaken with business partners to assess performance and enable them with the right support.

Partner feedback is proactively taken through various forums like townhalls, surveys and through other engagements; Engagement process helps ensure that our business partners are an integral part of our transformational initiatives towards EOHS, Quality, Innovation, Resource Efficiency, Operational Excellence and Compliances.

Partners are further engaged with the endeavour of cross-learning, knowledge-sharing, training and capability building, thus aiding in fostering strong long-term relationships with them.

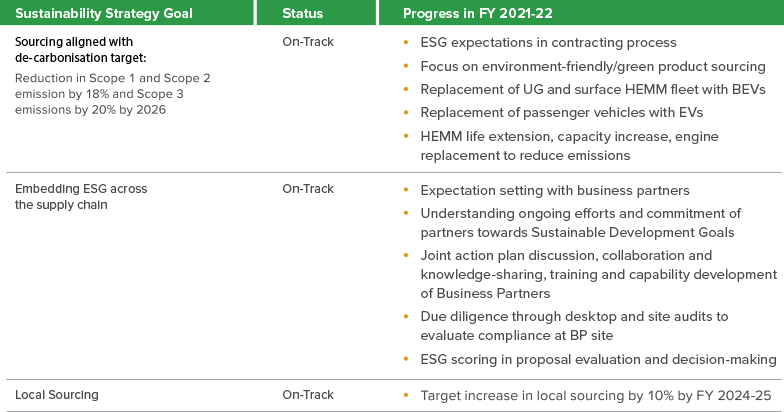

Commitment to Sustainable Development Goals is a key focus area for Hindustan Zinc. Our Responsible Sourcing initiative is aligned with the organisation’s SDG goals.

We believe in fostering strong and collaborative relationships with business partners on improving Environmental, Social and Governance (ESG) performance – in areas of climate change actions and transitioning to net-zero emission, safer operations and zero harm, resource conservation, diversity and inclusion, community development efforts, and stronger governance and compliance.

In pursuance of ESG goals laid out for our business partners, we have undertaken various initiatives in this regard.

FY 2021-22 witnessed massive supply chain disruptions, including shortages of coal, critical mining chemicals and operating supplies. Price volatility, inbound and outbound logistical challenges for inland and sea-borne cargo due to lockdowns, post-COVID effects and emerging situation from Russia-Ukraine war further challenged the supply chain at Hindustan Zinc. Water crisis management for smelter operations through logistics infrastructure development was another challenging area for the Company to ensure sustained operations.

We responded as a team to the various crises through meticulous planning.

Hindustan Zinc was one of the recipients of the CII DX award ‘Most Innovative Best Practice in Supply Chain & Logistics’ during FY 2021-22.

Hindustan Zinc team has been working on alternative products for graphite dispersant, which is a more sustainable product in terms of environment and health perspective.

As part of the product development journey, a cross-functional team, consisting of members from procurement, process, and R&D functions, undertook the following:

Conducted plant trials twice over a period of 6 months

The Benefits

Operational excellence

Relatively easy reagent preparation process

Graphite reduction

Cost impact

The alternative product is cost-efficient on TCO basis. The benefit was two-fold and helped in savings on procurement as well as smelter operating costs.

To get full visibility and control of the Company’s entire inventory, our supply chain team decided to consolidate the same at a single mega warehouse. The team felt the move would help bring in inventory optimisation, reduction in working capital, standardisation of spares, best-in-class storage facility, and a convenient use-and-pay model for seamless management of inventory.

TVS Supply Chain Solutions is our warehouse partner, and a central warehouse spanning over 3.5 lacs sq ft has been set up near Udaipur airport. Currently, store migration from smelter is under last leg of execution, to be followed by mines’ store migration. Inbound deliveries from business partners to mega warehouse and outbound deliveries to site locations have been initiated. This project is also crucial for integration of Use & Pay model for spare part management.

"At Hindustan Zinc, we are fully cognisant of the importance of strengthening our commercial function to unlock greater value for our business. To this end, we remain dedicatedly focussed on augmenting the pillars of our growth, through process automation and quality assurance in our sourcing. We are also advancing towards further consolidation of ordering and business partner rationalisation, which can act as key drivers of business growth. We aim to enhance our end-to-end delivery linked service contracts in mining, milling, smelting and power O&M areas to unleash enhanced value. At the same time, we shall sharpen our focus on ESG and digitalisation to monitor the performance of our business partners, to integrate it completely with our futuristic vision.”

Durairaj M Chief Commercial Officer