Smelters and Refinery

Expanding

Prudently

OPTIMISING METAL RECOVERY

During the year, we debottlenecked our smelting capacity to 1.123 mn MT per annum and expanded our minor metal recovery programme through completion of an ancillary plant at Chanderiya, our second such plant.

Our first zinc fumer project is complete and will be commissioned this year. This will lead to an annual recovery of valuable metals, including 32 MT of silver and 5,500 MT of zinc and lead from zinc residue, which otherwise would be wasted in jarofix. This project is a step forward in achieving the goal of zero solid waste and will also lead to overall waste reduction and lesser land requirement.

PERFORMANCE IN FY 2019-20

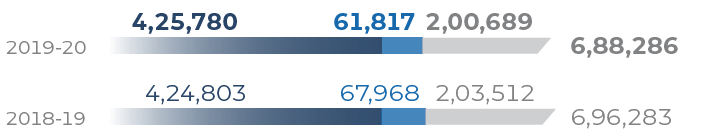

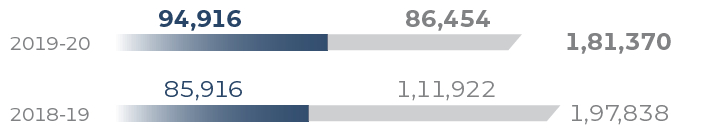

In FY 2019-20, we produced 8,69,656 MT of zinc-lead metal as compared to 8,94,121 MT in FY 2018-19 in line with mined metal availability and adversely impacted operations due to the lockdown in March 2020 to combat the spread of COVID-19. Zinc production at 6,88,286 MT was down by 1% y-o-y while integrated lead production was 1,81,370 MT, lower by 8% due to operational issues at Dariba Lead Smelter.

Refined Zinc

(MT)

Refined Lead

(MT)

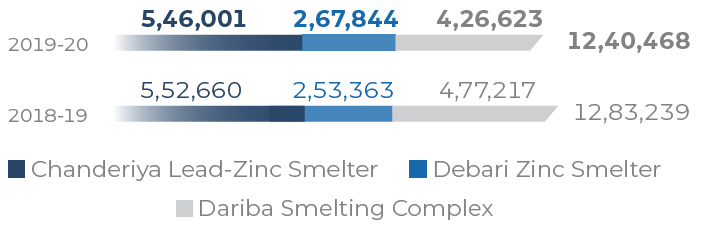

Sulphuric Acid

(MT)

Refined Silver

(MT)

A higher Current Efficiency (CE) leads to higher rate of zinc cathode production and lower power consumption. The global benchmark for CE in hydro zinc smelters is 92%, while the CLZS hydro smelter achieved CE of 93.2% by innovating modifications in the cell house and leaching section.

1% increase in CE is equivalent to 7.7 MT/day increase in cathode production and a 1% increase in CE is equivalent to 35 kWh/MT decrease in power consumption for production of zinc cathode.

KEY SAFETY AND SUSTAINABILITY INITIATIVES

- Commissioned a facility to produce sodium sulphate from RO reject at Dariba Smelting Complex (DSC), which will meet 50% demand of sodium sulphate via in-house production of 8,000 MTPA

- Implementing automation ideas through the Safety Innovation Cell to eliminate manual intervention

- Utilisation of Jarosite and jarofix was initiated in cement plants and increased road construction. It will further contribute towards reduction in environmental footprint as well as lower cost of production

- Plantation covering 20,000 square metres was completed over jarofix dump yards

- Switched from light diesel oil to PNG at pyrometallurgical plant at CLZS

MINOR METAL RECOVERY PROGRAMME

Our focus is on recovery of minor metals to bolster our operating profit, increase waste utilisation and reduce the cost of production.

Recovery of Cadmium, Cobalt and Antimony

A cadmium production plant to produce 2,600 MTPA of cadmium from smelter process residues is in the installation phase. In addition, feasibility studies for recovery of cobalt and antimony have been completed.

Ancillary Plant to Augment the ‘Waste to Wealth’ Journey

We commissioned an ancillary plant at Chanderiya and it is ready to treat copper dross. There are other units under construction to treat all residues from smelters including work-in-progress materials such as zinc oxide, purification cake, antimony dust and cadmium sponge, and is expected to be commissioned in FY 2020-21. The plant is likely to generate an additional revenue by producing lead bullion, zinc sulphate solution, copper sulphate solution, lead silver cake, antimony trioxide and cadmium metal. During the year, the copper matte treatment started at Dariba ancillary plant to produce additional copper sulphate.