Captive Power Plant (CPP)

Better Demand Planning

Driving Efficiencies

VISION

To supply reliable, efficient and sustainable power for Hindustan Zinc with zero harm and at lowest cost.

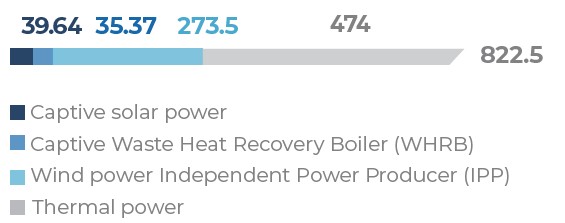

Power Capacity Mix in FY 2019-20

(MW)

RENEWABLE POWER BUSINESS

Investments in green energy enables us to reduce our carbon footprint on a sustainable basis.

In FY 2019-20, 0.7 MW of rooftop solar energy was commissioned, increasing the total solar power capacity to 39.64 MW. In addition, there is the Waste Heat Recovery Boilers (WHRB) capacity of 35.37 MW. Our wind energy plants are under long-term power purchase agreement with distribution companies.

During the year, we produced solar power of 79.38 mn units, waste heat energy of 146.24 mn units and wind power of 449.29 mn units, leading to a reduction of 5,80,995 MT of CO2 through green power.

FY 2019-20: PERFORMANCE SNAPSHOT

| CPP | Key Stats | |||

| Capacity (MW) |

PLF (%) |

APC (%) |

SCC (gms/kWh) |

|

| Chanderiya | 234 | 95 | 8.29 | 445 |

| Dariba | 160 | 94 | 8.21 | 443 |

| Zawar | 80 | 87 | 8.12 | 442 |

SAFETY INITIATIVES IMPLEMENTED IN THE YEAR

- Turbine enclosure in all three locations to separate hot and oil circuit, leading to reduction of fire hazards

- Wagon wheel clamper in the coal-handling plant wagon tippler area to reduce man-machine interaction

- Proximity switch in coal yard vehicle and locomotives across Hindustan Zinc CPP to reduce man-machine and machine-machine interactions

- Installed belt tear switch in all conveyors at Dariba and Zawar CPP for safe conveyor operation

THERMAL POWER BUSINESS

The coal-based thermal power plants generated 3,880 mn units in FY 2019-20, compared to 3,961 mn units in FY 2018-19. Higher power purchase from grid and lower metal production led to decline in power production. Overall, the specific coal consumption remained flattish at 444 gms/kWH in FY 2019-20 compared to 440 gms/kWH in FY 2018-19.

During the year, revamping of thermal power units was initiated with the aim of increasing the name plate capacity from 80 MW to 91.5 MW per unit in FY 2020-21. This will lead to higher power generation from each unit with the same quantity of steam leading to cost savings and also reduction in GHG emissions.

EFFICIENCY IMPROVEMENT INITIATIVES IMPLEMENTED IN FY 2019-20

| Initiative | Benefit |

| Vapour absorption machine chiller at CLZs CPP | Power saving of 0.7 MU annually |

| Single cooling water pump at CLZs CPP | Annual power saving of 0.7 MU |

| Converted 9.4 MW back pressure turbine of Hydro-1 to condensing type turbine | Enhanced utilisation of roaster and fumer excess steam, leading to 3 MW increase in power generation |

| Commissioned Variable Frequency Drive (VFD) in induced draft fan in both units at Dariba CPP | Energy saving of 3,600 kWh per day |

| Installed a carbon fibre shaft and Maya make fan blade in the cooling tower fan at Zawar | Reduction of total power consumption by 900 unit per day |

| Completed cleaning of online jet and bullet condenser at Dariba CPP in unit #5 | Saving in specific coal consumption by 1.5 gms/kWh at station |

| Deployed poclain to unload the rake | Reduction of unloading hours from 30 hours to 16 hours |

| Completed overhauling of CLZs CPP unit #2 | Recorded the best-ever overhauling time of 14.5 days, a reduction of two days over the previous best |

| Commissioned an in-house 25 KW inverter | Powered 13.8 KW floating solar at CLZs CPP raw water pond |