Strategic Priorities

Seizing Future

Opportunities

OUR ENABLERS

Business Excellence

It is our constant endeavour to achieve higher business excellence across all aspects of our operations by pushing the bar higher every day and setting new milestones. Our Business Excellence team ensures that best-in-class practices of identification and resolution of process bottlenecks are followed across the organisation. The adoption of latest technology, benchmarking, innovation and asset optimisation are the key enablers for us.

Digitalisation

We have strong focus on infusing a digital way of working across all verticals of operations. Digital connectedness of our mines and operations is driving process efficiency and safety. This focus has enabled us to continuously improve existing practices at every level of our value chain. All our underground operations are becoming safer, transparent and predictable.

Customer-centricity

Our widespread distribution network enables us to remain closer to our customers and serve them in an efficient manner through lower inventory-carrying costs and lead time. Further, we facilitate visits of internationally acclaimed industry experts to our customers’ facility to understand their process and suggest the appropriate technology, products and processes.

EXPANSION OF CAPACITIES

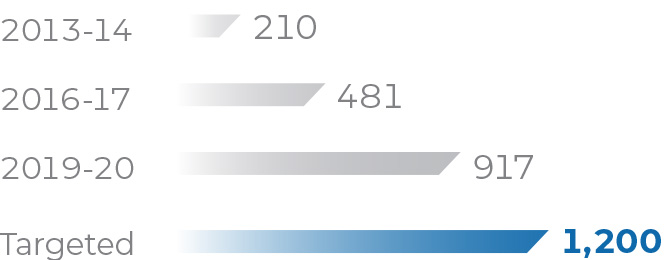

We have completed all major projects to build capacity of 1.2 mn MT per annum of mined metal. To achieve our vision of becoming the largest zinc-lead and silver company in the world, we will ramp up our production to the design capacity. Simultaneously, we are planning the next phase of mining expansion by increasing ore production to our target of 25 mn MT per annum. We are also fundamentally changing the way we operate to accelerate mine development rate, improve productivity and optimise cost.

Underground (UG) Production

(MIC production, kt)

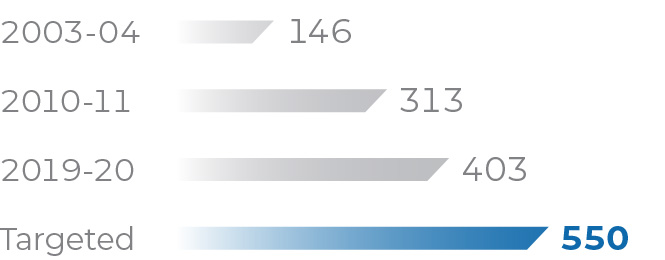

MAINTAINING A PORTFOLIO OF MINES WITH LONG LIFE

We are ensuring longevity of our mines by adding more to R&R than depletions through exploration in and around the existing and new deposits. All our deposits are open at depth and there is an opportunity to increase and upgrade resources through targeted surface and underground drilling. We are upgrading galena zone at Rampura Agucha, exploring a new ore body below shaft at Sindesar Khurd and establishing new lenses at Zawar and making deep extensions of the main lens at all mines.

Ramping up R&R

(total R&R MN MT)

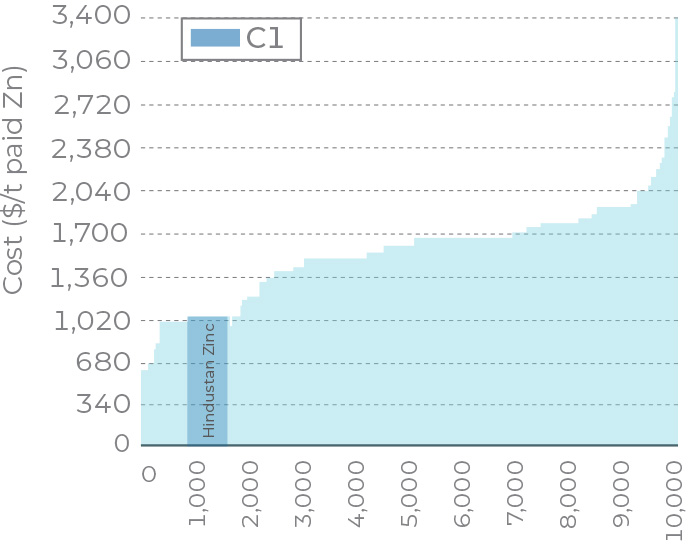

STRENGTHEN COST LEADERSHIP

We are among the lowest cost producers of zinc-lead in the world. To maintain this competitive advantage, we have a cost optimisation programme that focuses on reducing the cost of production of zinc. Apart from volume ramp-up, this involves use of technology, automation and innovation to increase ore-to-metal index, increase asset productivity, optimise power, increase efficiency and generate value from waste. Some of the initiatives like shaft hauling, digitalisation, autonomous vehicles, ancillary plants and the power optimisation, among others, have already been put in place and will lead to cost reduction in the coming year.

Keeping Costs under Check

(zinc cost curve, ranked by C1, composite cost)

Cumulative production paid Zn kt

Source: Wood Mackenzie

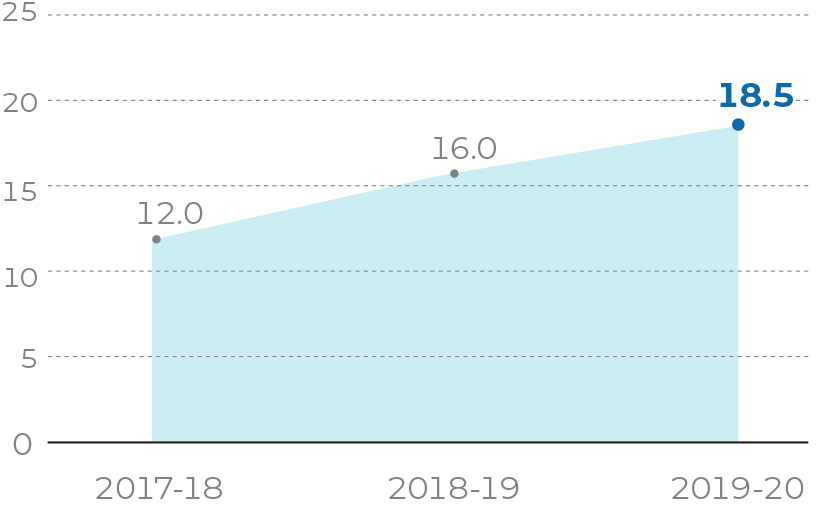

EXPANSION OF PRODUCT PORTFOLIO

Our foray into recovery of minor metal from smelter residues to produce high value-add forms of copper, cadmium, antimony and silver will cater to a growing market for these products. For this, we are significantly expanding our capacity for minor metal recovery over the next two years.

In our primary metals portfolio, we have adopted a customer-centric approach to increase penetration of VAP by increasing awareness about technical and commercial benefits of VAP. In addition, we are developing new products by identifying downstream applications. In the coming year, we plan to launch new products in lead alloys and increase the penetration of zinc alloys.

Rising Share of VAP in Our Sales

(%)

TRANSITION TO A CIRCULAR ECONOMY

We are using technology and innovation to reduce-reuse-recycle waste and restore natural systems, including water and land, to transition to a circular economy. We are embracing low-carbon and less-emission technologies, increasing renewable energy capacity and constantly reducing the GHG emission of our operations. We are increasing local sourcing to bolster local economy and community well-being. Product stewardship will be a focus area.

Sustainability Goal 2025

0.5MNtCO2e

GHG emission savings from base year 2017

5.0x

Water positive from current 2.41x

3.0x

Increase in gainful utilisation of smelter waste

100%

Responsible sourcing